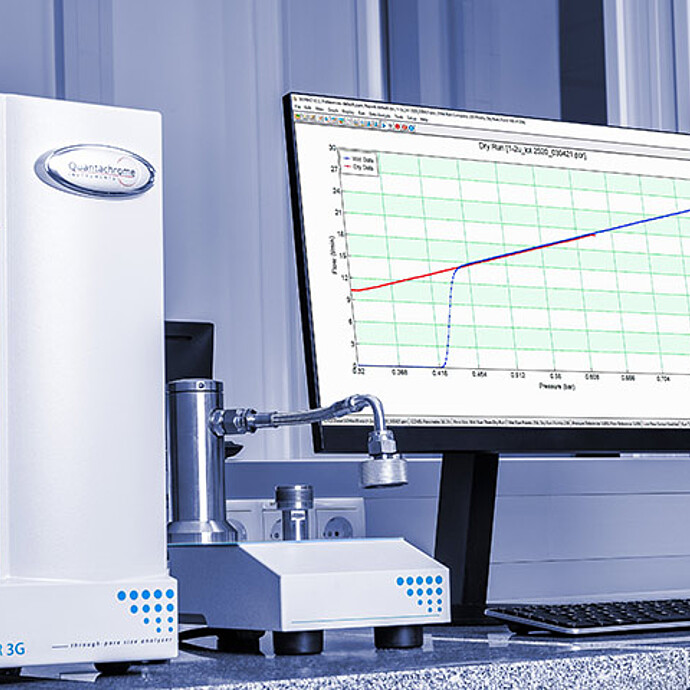

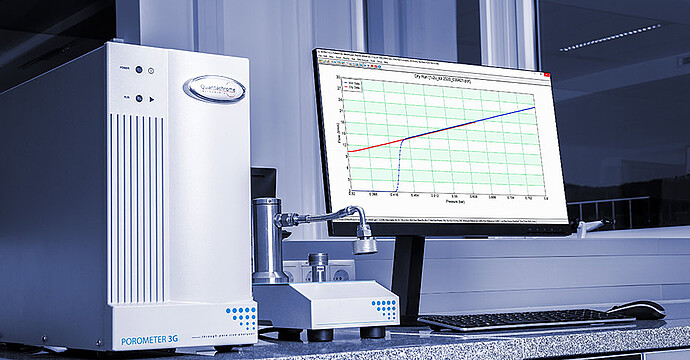

Capillary Flow Porometers for Through-Pores:

Porometer 3G

- Measures pores from 0.07 μm to 100 μm

- Used with an inlet gas source with up to 100 psi (6.9 bar)

Porometer 3G instruments deliver accurate and repeatable through-pore size measurements within 30 minutes for any sample. Their simplified operation and general measurement speed make these capillary flow porometers the clear choice for through-pore size distribution measurements of filtration media. Depending upon the pore size range and flow-through characteristics of your samples, there’s a Porometer 3G that’s right for you.

Key features

No need for calibrations: saving operator time and effort

The pressure sense line in Porometer 3G instruments measures the pressure directly at the sample, and is therefore unaffected by changing flow rates. In contrast, conventional capillary flow porometers measure the pressure at some fixed point prior to applying the sample, and use sample-specific flow path calibrations to predict the pressure at the sample. Because the amount of airflow within this path affects the pressure gradient that exists, each sample type requires a calibration to be performed and applied. The unique design of Porometer 3G eliminates the need for calibrations. This means much less effort and ultimately more accurate measurements.

Automatic pressure regulation ensures ideal measurement conditions every time

Porometer 3G instruments use an intelligent pressurization routine designed to ensure results within equilibrium throughout the measurement. This routine eliminates the problems that come with conventional systems, due to the fact that measurements made with a constant ramp rate, which is too fast, provide smaller-than-correct pore sizes, as they don’t allow enough time for equilibrium to be achieved at each pressure data point. Conversely, similar measurements made too slowly accentuate the effects of wetting fluid evaporation, providing larger-than-correct pore sizes. Porometer 3G units automatically regulate the pressure - which leads to accurate results independent of the settings.

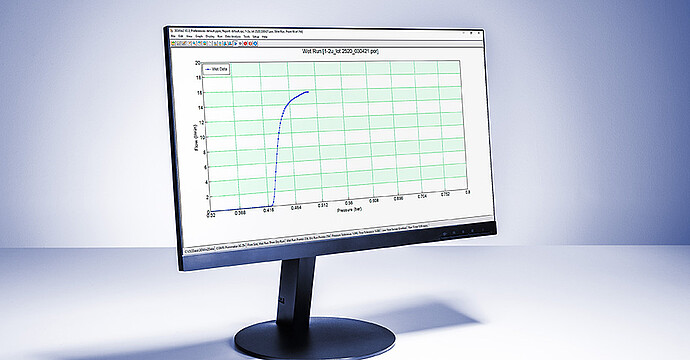

Complete through-pore size distribution for the full set of data

Porometer 3G makes all flow measurements on a single flow meter, and thus obtains a continuous account of through-pores present in your material. This includes the crucial region between the maximum and mean pore sizes. Capillary flow porometers that switch measurement devices after the bubble point is reached run the risk of missing a portion of this data. You can rely on Porometer 3G to deliver a complete data set.

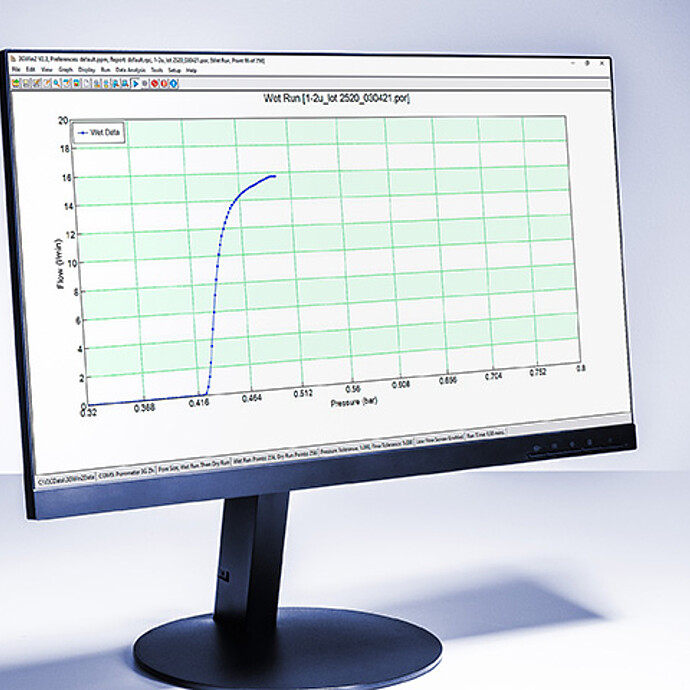

Wet-then-dry, dry-then-wet – you choose

Capillary flow porometry measurements involve both a “wet curve” (the flow resulting from the expulsion of wetting fluid from pores at different pressures) and a “dry curve” (the flow through the material over the pressure range of the measurement when wetting fluid is present). Measuring wet-then-dry is much simpler for the operator and does not involve opening the sample holder in the middle of the experiment. Dry-then-wet measurements remove concerns about potential effects on the sample during the creation of the wet curve. Both measurements are available on all Porometer 3G instruments. You can enjoy the workflow ease of wet-then-dry measurements and still have the option to perform dry-then-wet measurements when samples warrant it.

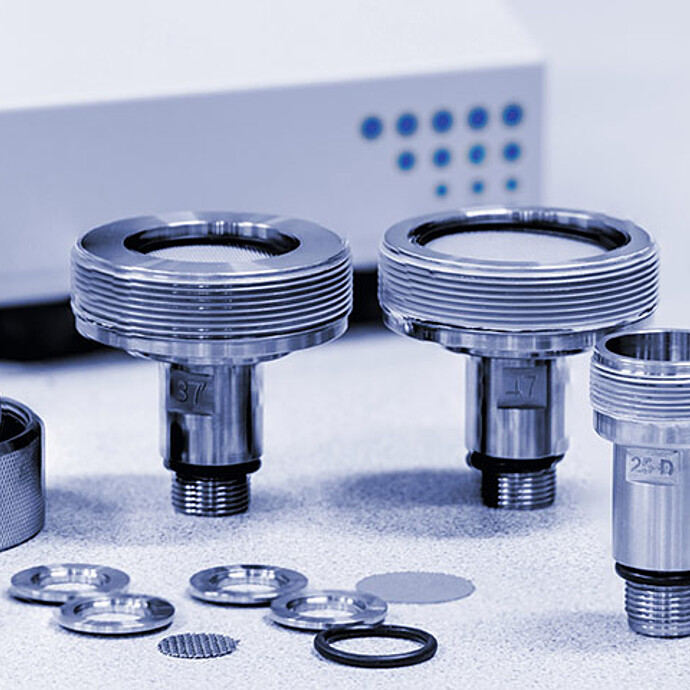

Adapts to the wide range of sample requirements in your lab

All Porometer 3G instruments have the ability to use different shape factors and different fluids in order to develop a test method specifically catered to your sample measurement needs. In addition, their design is perfect for adapting to samples of various sizes and shapes via external holders for use with hollow fiber, solid piece, or rigid tubular configurations.

Technical specifications

| 3G micro | 3G z | 3G zH | |

| Pore size, minimum | 0.07 µm | <0.03 µm | <0.02 µm |

| Pore size, maximum | 100 µm | 500 µm | 500 µm |

| Pressure controllers | 1 | 2 | 2 |

| Controller #1 | 0 psi to 100 psi | 0 psi to 30 psi | 0 psi to 30 psi |

| Controller #2 | n/a | 0 psi to 300 psi | 0 psi to 500 psi |

| Pressure sensors | 2 | 3 | 3 |

| Sensor #1 | 0 psi to 5 psi | ||

| Sensor #2 | 0 psi to 100 psi | ||

| Flow sensors | 1 | 1 | 2 |

| Sensor #1 | 0 L/min to 100 L/min | 0 L/min to 100 L/min (standard) | 0 L/min to 10 L/min |

| Sensor #2 | n/a | n/a | 0 L/min to 200 L/min |

| Flow sensor switching | n/a | manual | auto |

| Pressure sensing accuracy | ±0.05 % f.s. | ||

| Pressure resolution | 16 bit A/D equivalent | ||

| Flow sensor type | Precision thermal mass flow | ||

| Flow sensor settling time | <2 seconds | ||

| Flow sensor temperature coefficient | <0.05 %/°C (15 °C to 45 °C) | ||

| General specifications | |||

| Electrical properties | 90 V to 240 V AC, 50/60 Hz | ||

| Main control unit dimensions (H x D x W) | 40 cm x 45 cm x 19 cm (15.8 in x 17.8 in x 19 in) | ||

| Sample holder block dimensions (H x D x W) | 24 cm x 32 cm x 15 cm (9.5 in x 12.6 in x 6 in) | ||

| This table shows standard configurations. Different pressure and flow rate ranges are available for some models. | |||

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Characterization of Face Masks Application Reports

-

Differentiating Filter Media by Capillary Flow Porometry Application Reports

-

E-Book - Field Guide to Battery Materials Characterization – Revised and Updated Application Reports

-

Material Brief: Characterization of Copper Sintered Powder Wicks - Porometer 3G Application Reports

-

Material Brief: Geotextile Membranes - Porometer 3G Application Reports

-

Material Brief: Hollow Fiber Analysis - Porometer 3G zh Application Reports

-

Material Brief: Pore Size of a Polymeric Scaffold - Porometer 3G micro Application Reports

-

Measuring Pore Size in the Walls of Hollow Fiber Membranes Application Reports

-

Pore Size Measurement of Track Etched Membranes by Capillary Flow Porosimetry Application Reports

-

Structural Characterization of Battery Components Application Reports

-

NEW HORIZONS IN PARTICLE ANALYSIS Brochures

-

Porometer 3G Brochure Brochures

Consumables

Consumables

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.

3G TOP SUPPORT SCREEN FOR 50 mm HOLDER

Porometer 3G micro | z | zH